The challenge of delivering perfect color and meeting quality/consistency requirements is becoming increasingly complex for packaging printers and converters. In addition to rising brand owner demands, printers are faced with an increased pace and complexity of required technological innovation—at a time when profit margins are very tight. Add to that increasing requirements to meet new industry standards, an aging workforce, and the scarcity of true color experts…and the challenges can be extremely daunting!

For that reason, Baldwin Vision Systems has introduced and continues to develop new color management tools that directly address these challenges. Among the innovations are complete workflow solutions that are software-based (requiring no investment in hardware or press modifications), automation that greatly simplifies the science of color production (reducing reliance on a handful of color experts who can’t be on every press for every shift at every plant), and inline color measurement technology that is affordable and adaptable for even small printing and converting operations.

Commercial and newspaper printers can reduce makeready time and ensure that the entire press run remains within customer-specified color tolerances. Our closed-loop color control solutions adjust the press automatically to maintain accurate control over four-color process and special colors throughout the run. Visual and audio alarms alert operators to errors and out-of-tolerance conditions, allowing for prompt resolution and minimum impact on production.

Our solutions can not only help you to achieve industry standard certifications, but will also ensure that you print to those standards (G7®, ISO, house standards) on every print run. Minimize rebates and reruns with quantified job quality. Monitor and improve job and equipment performance with powerful statistical reports on density, dot gain, trap and print contrast.

Closed-Loop Color Control

CLC+ Color and Register Control

For Commercial and Newspaper press applications.

Closed-loop color density control and register control in one system.

Color Control with SpectralCam™

For Commercial press applications.

Spectral, L*a*b*, Delta-E, Density, and Gray Balance control at full press speed.

Color Measurement

Color Measurement with DeltaCam™

For Packaging & Converting applications.

Accurate inline spectral measurement on film, paper or board.

Color/Ink Management

ColorTrack™

For Packaging & Converting applications.

Seamlessly integrates with ink recipe software to dramatically reduce the number of ink corrections needed to achieve optimal color.

Ink Delivery

RIC Remote Ink Control

For Packaging & Converting, Commercial, and Newspaper press applications.

A highly scalable, budget-friendly solution for replacing obsolete or unsupported press controls.

Monitoring & Reporting

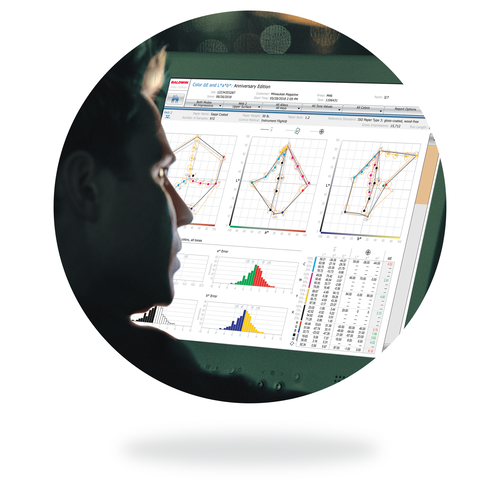

Data Central® Reporting

For Commercial and Newspaper press applications.

Optional enhancement for Color Control with SpectralCam™, Register Guidance or Ribbon Control with MultiCam®.